NEW ORLEANS — The U.S. Department of Defense has a new way of helping troops who have lost a limb. The prosthetic is attached to your body and moves like a real one.

And the new technology was perfected, in part, in Southeast Louisiana. It all started six years ago when we followed the first person in the U.S. to get a working, 3D-printed thumb.

Imagine being a military veteran and losing an arm or leg in combat. Now imagine after that life-changing injury, the U.S. Department of Defense says its latest research can help make you whole.

“There are a lot of wounded warriors who could benefit from the technology in many different areas, and not just the legs, but arms,” said Andy Christensen, a board member at Integrum.

For 33 years, Integrum in Sweden, has been working on that type of technology. It started with a father's idea of a dental implant in the 1960s, anchoring a metal rod solidly into the jaw bone, then snapping the porcelain tooth on. So, his son thought the same process could be used for limbs. It got the attention of the DOD which brought a clinical trial to Southeast Louisiana.

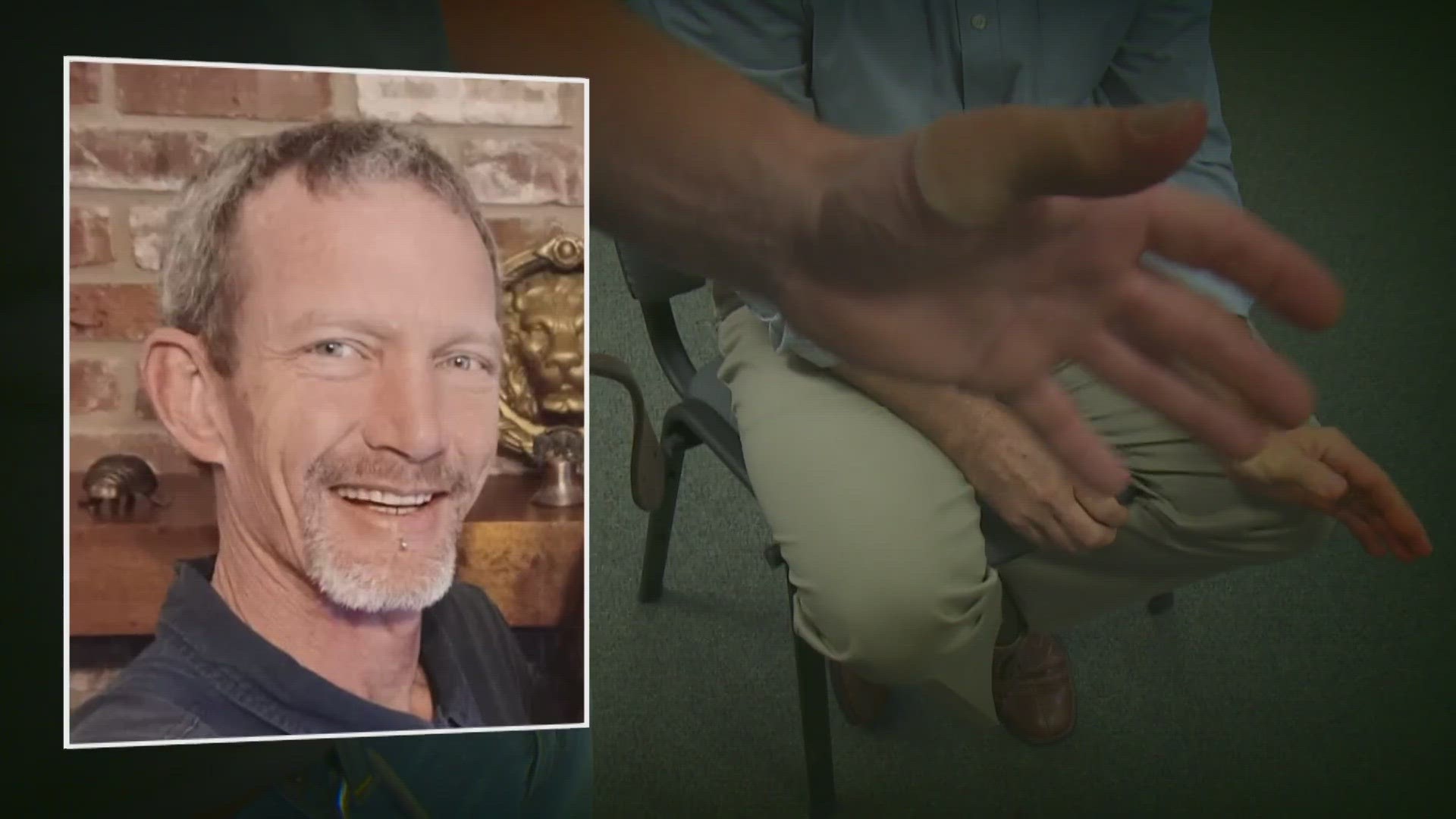

As little boy on the family farm, Jackson Caplis helped his dad fix tractors, and reengineered toy cars to go faster, but he could have never imagined he'd become the bionic mechanic, the first in the U.S. to get a 3D-printed body part. It all started on the job in Port Fourchon.

“We were just fixing a piece of equipment, and a pin sheared off and the piece of equipment, weighs 56,000 pounds, fell on top on my thumb. We didn't have a piece of equipment big enough to get it off. So, I stayed underneath it for 34 minutes,” said Jackson Caplis.

He was air lifted to University Medical Center in New Orleans.

“That's the time when I realized, well there goes my life because that's all I knew was mechanics. Now I don't have a thumb, and you've got to have it to be a mechanic,” remembers Caplis.

It's what he loved and was his livelihood. His new work was nearly half the salary. He lost his home. A friend took his family of five, into his home.

“What did that do to your lifestyle, Jackson?” he was asked.

“It wasn't easy. Times are tough, you do what you've got to do,” he replied.

The simple daily things, like putting on socks, using a cell phone, opening a bag of food, that we take for granted, became difficult. But then Jackson got life-changing news. Metairie hand surgeon Dr. Eric George was chosen to perform the first surgery of its kind in the U.S., to give Jackson a working, gripping thumb back, not just one for cosmetics. His mother Mary sits nervously in the waiting room the day of surgery.

“I just want it to be the first successful transplant in the United States. I want his dreams to come true,” said Mary Caplis, Jackson’s mother.

In 2017, we got to scrub into the O.R. to document this pioneering surgery. An international medical team is gathered. The thumb bone is drilled so the metal rod can be permanently inserted. Every angle has to be precise. Constant measurements are taken by fluoroscope. Doctors check the tension of the metal rod over, and over again.

In the O.R., after about two hours with a team of two dozen people, our patient now has a permanent implant so he can have a thumb for the rest of his life.

As weeks go by, Jackson has a temporary thumb and is in physical rehab to make his hand muscles stronger. Remember his goal is to get a strong grip back so he can work as a mechanic again.

Years later as Jackson moves to Colorado, he is feeling whole and working again. His new thumb is printed with his favorite team logo, Alabama.

“Roll Tide,” he shouts.

It can come on and off. That was a lesson learned when he ordered a drink at a drive through.

"I didn't have my thumb on and thought I did, and I went to grab it and, whew, right out the bottom,” he told KKTV-TV 11-News, in Colorado Springs.

Today he works as an auto mechanic in Little Rock. He has two 3D-printed thumbs, that Alabama one, and a plain one for work. They are made of hard plastic not metal, since he works around high voltage. His boss says he's one of the best mechanics he's ever seen, but nothing makes him more at peace than his family, his dogs, and being able to grip the handle bars of his motorcycle.

In the U.S., this is only FDA approved for leg amputees. The research is continuing at big university surgical centers.

► Get breaking news from your neighborhood delivered directly to you by downloading the new FREE WWL-TV News app now in the IOS App Store or Google Play.